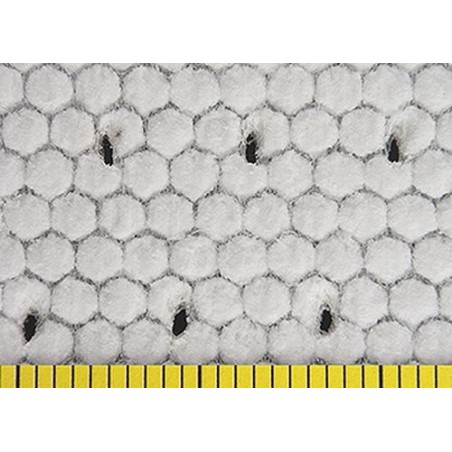

LANTOR COREMAT XM - resembles a honeycomb, it is easier to arrange on curves and bends. It can be laminated on a radius equal to its thickness. It is produced in thicknesses of 2,3,4 and 10 mm. It allows you to save up to 60% of resin. LANTOR COREMAT are hand laminating core mats that increase the rigidity of the laminate, reduce its weight, and reduce labor and resin consumption. This is an original development of the Lantor company from the Netherlands, their introduction to the market 30 years ago completely changed the structure and properties of glass-polyester laminates. So far, very heavy laminates have become lighter and stiffer. Lantor Coremat is a non-woven polyester mat filled with gas-filled polymer microspheres. The microspheres are only 20 µm in diameter and evenly distributed throughout the volume of the nonwoven fabric. The Lantor Coremat mat is produced in several thicknesses and two types. 1 mm of the mat thickness is replaced by one layer of glass mat weighing 450 g / m2. The mat is used as the core material, i.e. it must always be in the center of the laminate, symmetrically surrounded by layers of glass mat. The share of the LANTOR COREMAT mat should be 40-60% of the laminate thickness. In the case of thin laminates, the use of Lantor Coremat gives even a twofold increase in the stiffness of the laminate, while in the case of, for example, a 10 mm laminate with a 5 mm core of the Lantor Coremat mat, the stiffness increases by only 10%, but the weight of the laminate decreases by 2.7 kg / m2, resin consumption drops by 1.3 kg / m2, and it takes as many as 4 work steps to make this laminate. Therefore, the sales of the Lantor Coremat mat are growing year by year, it is characteristic that after a short time the manufacturers of laminates cannot imagine further work without COREMAT. The mat is used both for the construction of molds, they are therefore lighter, stiffer, and thanks to the lower resin content, they withstand even twice as many deformations. Lantor Coremat can be used literally everywhere: from boats, yachts, car body parts, trucks and buses, to sports equipment, industrial components ...

Dimensions: